Permadec GRP Cantilever Panels

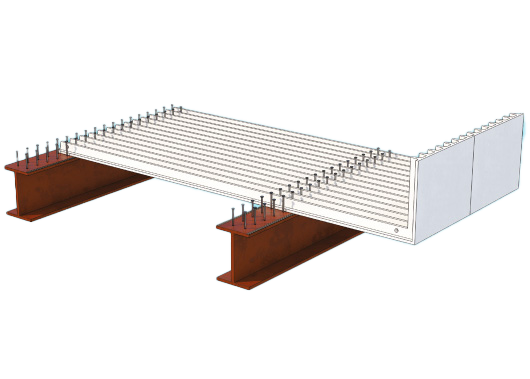

Permadec Cantilever Panels are engineered GRP permanent formwork systems designed to support bridge deck cantilevers without propping. Integrated edge upstands, optional edge protection sockets, coordinated rib spacing and bespoke clamping systems enhance safety, reduce temporary works and improve programme certainty.

Permadec Cantilever Panels are designed on a project-specific basis to suit deck depth, span and construction loading requirements. Cantilever projections are determined by structural capacity, with typical applications extending beyond 1.5 m from the edge of the top girder. Panels are self-supporting under standard design conditions and are engineered to avoid the need for propping where feasible.

Rib spacing is coordinated with shear stud layouts, with GRP apertures incorporated over studs where required to minimise onsite clashes and ensure compatibility with the steel arrangement.

Optional edge protection sockets can be incorporated to suit project requirements, accommodating full hoarding or mesh systems. Integrated upstands may be formed to deck depth or extended to suit secondary pours such as kerbs.

A bespoke clamping system is designed and supplied by Permadec for each application, providing secure attachment without reliance on external edge platforms or additional temporary walkways.

Depending on girder configuration, panels may be installed at ground level prior to beam lift or positioned in situ using suitable site lifting equipment. Once beams are landed, the system provides a stable working platform with integrated edge protection.

Product Features

Technical Specifications

Cantilever projection, deck depth and construction loading for Permadec GRP permanent formwork are determined by project-specific structural design parameters.

Technical Specifications

Cantilever projection, deck depth and construction loading for Permadec GRP permanent formwork are determined by project-specific structural design parameters.

Permadec GRP Cantilever Panel Projects

More Products

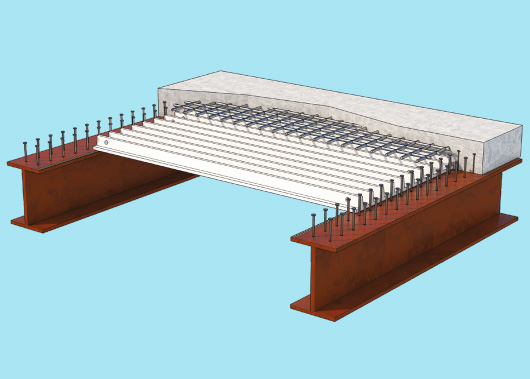

Permadec GRP Deck Panels

Our standard range of panels normally start at about 1m but we can accommodate moulds all the way up to 5m in length.

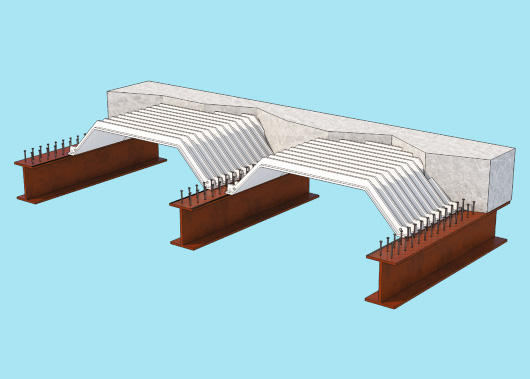

Permadec GRP Haunched Formwork Panels

Permadec can design and manufacture specially shaped haunched panels which can be used to reduce a deck thickness but also to avoid or suspend additional services beneath the soffit.

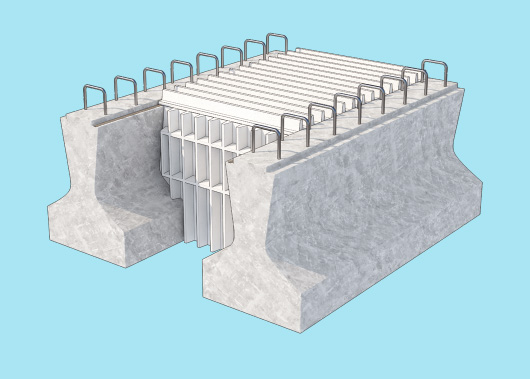

GRP Composite Infill Formwork Panels

Combining a deck panel with a diaphragm panel, Permadec can offer the contractor a complete formwork solution for slab and side concrete pours.

Get in touch

For more information please contact one of our sales advisors on +61 2 9052 4975 email at sales@permadec.com.au or fill our this form.

"EMJ Plastics Limited were engaged to design, manufacture and deliver permanent formwork panels (Permadec) for a new road bridge in Newhaven, East Sussex. They were superb throughout the procurement, design and manufacturing stage. The Permadec system is extremely fast and easy to install especially when using the lifting frame to load out multiple panels at a time. The system seals really well requiring no additional protection when pouring the concrete deck above, even when working over a live railway. I would happily use this system and EMJ Plastics Ltd again."

Christopher Buckle, Senior Site Agent at BAM Nuttall Ltd