Permadec GRP Haunched Formwork Panels

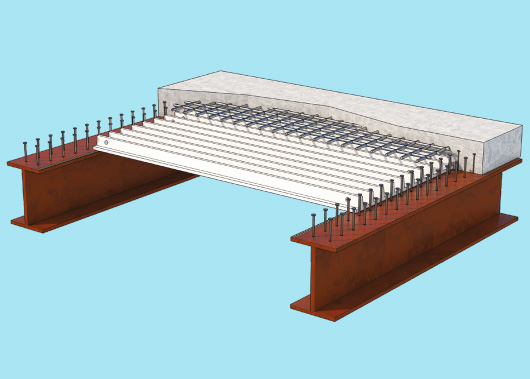

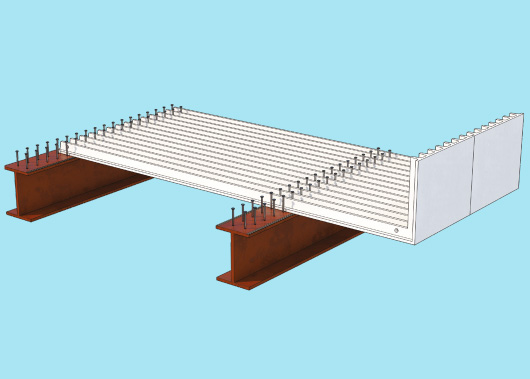

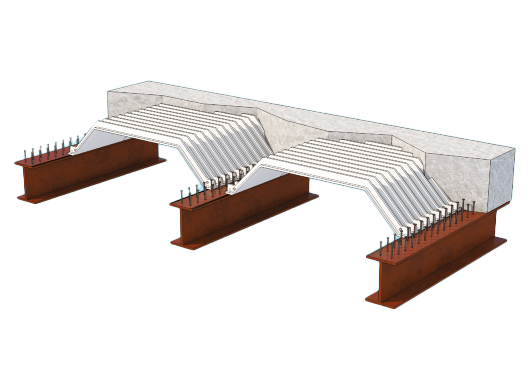

Permadec Haunched Panels are engineered GRP permanent formwork incorporating integrated haunch geometry within the panel profile. Designed for steel girder bridge decks, they reduce overall structural depth while maintaining self-supporting performance under full construction loading.

Permadec Haunched Panels are designed on a project-specific basis to suit deck depth, span and haunch angle requirements. The haunch profile is formed within the GRP panel, allowing structural transitions to be achieved without increasing steel rib depth or introducing secondary formwork.

Panels are self-supporting under construction loading and are engineered to carry full wet concrete and live loads in accordance with project design parameters.

Installation may be undertaken onto either the top or bottom flange of steel girders, depending on project configuration.

Rib spacing is coordinated to align with the reinforcement on site.

Each panel is designed case-by-case to suit the required haunch depth and geometry.

Product Features

Technical Specifications

Haunch depth, angle and structural capacity are determined by project-specific design parameters for Permadec GRP permanent formwork panels.

Technical Specifications

Haunch depth, angle and structural capacity are determined by project-specific design parameters for Permadec GRP permanent formwork panels.

Permadec GRP Haunched Formwork Panel Projects

More Products

Permadec GRP Deck Panels

Our standard range of panels normally start at about 1m but we can accommodate moulds all the way up to 5m in length.

Permadec GRP Cantilever Panels

A major cost advantage is achieved when using our specially designed cantilever panels to avoid the need for propping off the side of a bridge or concrete deck structure.

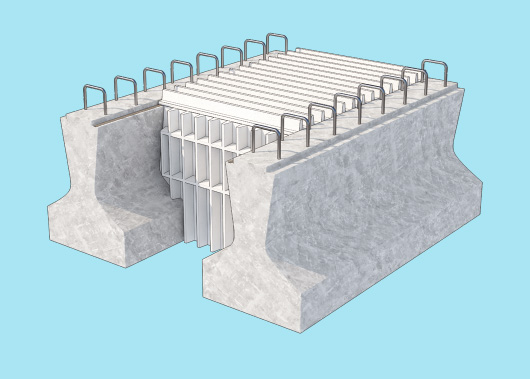

GRP Composite Infill Formwork Panels

Combining a deck panel with a diaphragm panel, Permadec can offer the contractor a complete formwork solution for slab and side concrete pours.

Get in touch

For more information please contact one of our sales advisors on +61 2 9052 4975 email at sales@permadec.com.au or fill our this form.

"EMJ Plastics Limited were engaged to design, manufacture and deliver permanent formwork panels (Permadec) for a new road bridge in Newhaven, East Sussex. They were superb throughout the procurement, design and manufacturing stage. The Permadec system is extremely fast and easy to install especially when using the lifting frame to load out multiple panels at a time. The system seals really well requiring no additional protection when pouring the concrete deck above, even when working over a live railway. I would happily use this system and EMJ Plastics Ltd again."

Christopher Buckle, Senior Site Agent at BAM Nuttall Ltd